It was a week before DeFilippo recovered sufficiently from his infections to come off the ventilator, and it was two months before he left the hospital. Weak and debilitated, he lost his limousine business and his home, and he had to move in with his sister. The tube draining bile still dangled from his abdomen; when he was stronger, I was going to have to do surgery to reconstruct the main bile duct from his liver. But he survived. Most people in his situation do not.

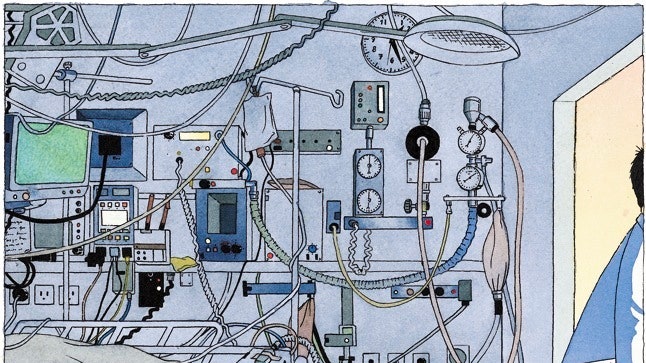

Here, then, is the puzzle of I.C.U. care: you have a desperately sick patient, and in order to have a chance of saving him you have to make sure that a hundred and seventy-eight daily tasks are done right—despite some monitor’s alarm going off for God knows what reason, despite the patient in the next bed crashing, despite a nurse poking his head around the curtain to ask whether someone could help “get this lady’s chest open.” So how do you actually manage all this complexity? The solution that the medical profession has favored is specialization.

I tell DeFilippo’s story, for instance, as if I were the one tending to him hour by hour. But that was actually Max Weinmann, an intensivist (as intensive-care specialists like to be called). I want to think that, as a general surgeon, I can handle most clinical situations. But, as the intricacies involved in intensive care have mounted, responsibility has increasingly shifted to super-specialists like him. In the past decade, training programs focussed on critical care have opened in every major American city, and half of I.C.U.s now rely on super-specialists.

Expertise is the mantra of modern medicine. In the early twentieth century, you needed only a high-school diploma and a one-year medical degree to practice medicine. By the century’s end, all doctors had to have a college degree, a four-year medical degree, and an additional three to seven years of residency training in an individual field of practice—pediatrics, surgery, neurology, or the like. Already, though, this level of preparation has seemed inadequate to the new complexity of medicine. After their residencies, most young doctors today are going on to do fellowships, adding one to three further years of training in, say, laparoscopic surgery, or pediatric metabolic disorders, or breast radiology—or critical care. A young doctor is not so young nowadays; you typically don’t start in independent practice until your mid-thirties.

We now live in the era of the super-specialist—of clinicians who have taken the time to practice at one narrow thing until they can do it better than anyone who hasn’t. Super-specialists have two advantages over ordinary specialists: greater knowledge of the details that matter and an ability to handle the complexities of the job. There are degrees of complexity, though, and intensive-care medicine has grown so far beyond ordinary complexity that avoiding daily mistakes is proving impossible even for our super-specialists. The I.C.U., with its spectacular successes and frequent failures, therefore poses a distinctive challenge: what do you do when expertise is not enough?

On October 30, 1935, at Wright Air Field in Dayton, Ohio, the U.S. Army Air Corps held a flight competition for airplane manufacturers vying to build its next-generation long-range bomber. It wasn’t supposed to be much of a competition. In early evaluations, the Boeing Corporation’s gleaming aluminum-alloy Model 299 had trounced the designs of Martin and Douglas. Boeing’s plane could carry five times as many bombs as the Army had requested; it could fly faster than previous bombers, and almost twice as far. A Seattle newspaperman who had glimpsed the plane called it the “flying fortress,” and the name stuck. The flight “competition,” according to the military historian Phillip Meilinger, was regarded as a mere formality. The Army planned to order at least sixty-five of the aircraft.

A small crowd of Army brass and manufacturing executives watched as the Model 299 test plane taxied onto the runway. It was sleek and impressive, with a hundred-and-three-foot wingspan and four engines jutting out from the wings, rather than the usual two. The plane roared down the tarmac, lifted off smoothly, and climbed sharply to three hundred feet. Then it stalled, turned on one wing, and crashed in a fiery explosion. Two of the five crew members died, including the pilot, Major Ployer P. Hill.

An investigation revealed that nothing mechanical had gone wrong. The crash had been due to “pilot error,” the report said. Substantially more complex than previous aircraft, the new plane required the pilot to attend to the four engines, a retractable landing gear, new wing flaps, electric trim tabs that needed adjustment to maintain control at different airspeeds, and constant-speed propellers whose pitch had to be regulated with hydraulic controls, among other features. While doing all this, Hill had forgotten to release a new locking mechanism on the elevator and rudder controls. The Boeing model was deemed, as a newspaper put it, “too much airplane for one man to fly.” The Army Air Corps declared Douglas’s smaller design the winner. Boeing nearly went bankrupt.

Still, the Army purchased a few aircraft from Boeing as test planes, and some insiders remained convinced that the aircraft was flyable. So a group of test pilots got together and considered what to do.

They could have required Model 299 pilots to undergo more training. But it was hard to imagine having more experience and expertise than Major Hill, who had been the U.S. Army Air Corps’ chief of flight testing. Instead, they came up with an ingeniously simple approach: they created a pilot’s checklist, with step-by-step checks for takeoff, flight, landing, and taxiing. Its mere existence indicated how far aeronautics had advanced. In the early years of flight, getting an aircraft into the air might have been nerve-racking, but it was hardly complex. Using a checklist for takeoff would no more have occurred to a pilot than to a driver backing a car out of the garage. But this new plane was too complicated to be left to the memory of any pilot, however expert.

With the checklist in hand, the pilots went on to fly the Model 299 a total of 1.8 million miles without one accident. The Army ultimately ordered almost thirteen thousand of the aircraft, which it dubbed the B-17. And, because flying the behemoth was now possible, the Army gained a decisive air advantage in the Second World War which enabled its devastating bombing campaign across Nazi Germany.

Medicine today has entered its B-17 phase. Substantial parts of what hospitals do—most notably, intensive care—are now too complex for clinicians to carry them out reliably from memory alone. I.C.U. life support has become too much medicine for one person to fly.

Yet it’s far from obvious that something as simple as a checklist could be of much help in medical care. Sick people are phenomenally more various than airplanes. A study of forty-one thousand trauma patients—just trauma patients—found that they had 1,224 different injury-related diagnoses in 32,261 unique combinations for teams to attend to. That’s like having 32,261 kinds of airplane to land. Mapping out the proper steps for each is not possible, and physicians have been skeptical that a piece of paper with a bunch of little boxes would improve matters much.

In 2001, though, a critical-care specialist at Johns Hopkins Hospital named Peter Pronovost decided to give it a try. He didn’t attempt to make the checklist cover everything; he designed it to tackle just one problem, the one that nearly killed Anthony DeFilippo: line infections. On a sheet of plain paper, he plotted out the steps to take in order to avoid infections when putting a line in. Doctors are supposed to (1) wash their hands with soap, (2) clean the patient’s skin with chlorhexidine antiseptic, (3) put sterile drapes over the entire patient, (4) wear a sterile mask, hat, gown, and gloves, and (5) put a sterile dressing over the catheter site once the line is in. Check, check, check, check, check. These steps are no-brainers; they have been known and taught for years. So it seemed silly to make a checklist just for them. Still, Pronovost asked the nurses in his I.C.U. to observe the doctors for a month as they put lines into patients, and record how often they completed each step. In more than a third of patients, they skipped at least one.

The next month, he and his team persuaded the hospital administration to authorize nurses to stop doctors if they saw them skipping a step on the checklist; nurses were also to ask them each day whether any lines ought to be removed, so as not to leave them in longer than necessary. This was revolutionary. Nurses have always had their ways of nudging a doctor into doing the right thing, ranging from the gentle reminder (“Um, did you forget to put on your mask, doctor?”) to more forceful methods (I’ve had a nurse bodycheck me when she thought I hadn’t put enough drapes on a patient). But many nurses aren’t sure whether this is their place, or whether a given step is worth a confrontation. (Does it really matter whether a patient’s legs are draped for a line going into the chest?) The new rule made it clear: if doctors didn’t follow every step on the checklist, the nurses would have backup from the administration to intervene.

Pronovost and his colleagues monitored what happened for a year afterward. The results were so dramatic that they weren’t sure whether to believe them: the ten-day line-infection rate went from eleven per cent to zero. So they followed patients for fifteen more months. Only two line infections occurred during the entire period. They calculated that, in this one hospital, the checklist had prevented forty-three infections and eight deaths, and saved two million dollars in costs.